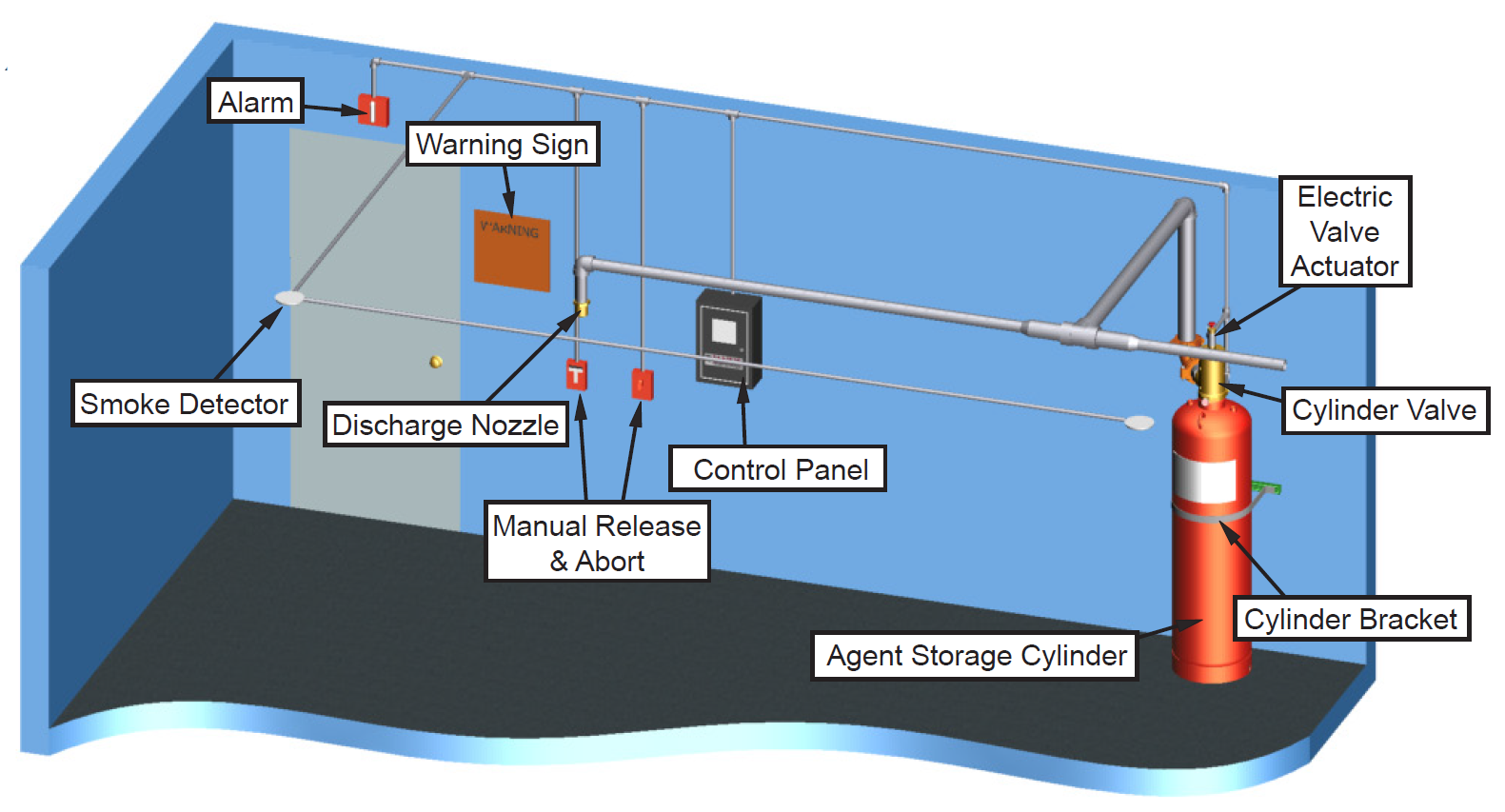

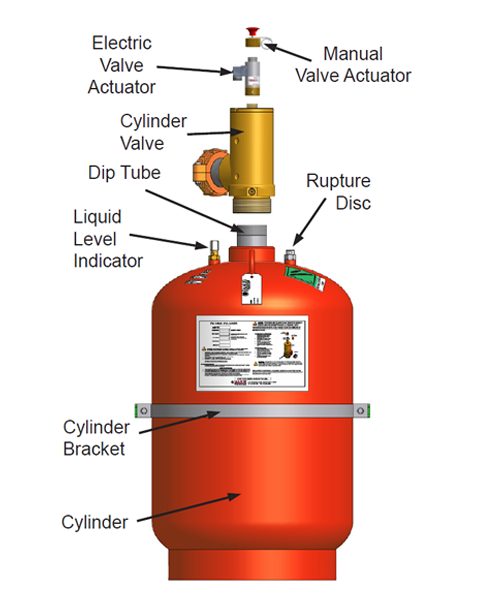

FM-200 Suppression Systems

- Safe for human occupancy.

- Zero Ozone Depletion Potential (ODP)

- Discharges in 10 seconds or less to extinguish fires rapidly, minimizing damage to high value assets.

- Appears on US Environmental Protection Agency (EPA) Significant New Alternatives Policy (SNAP) list

- Designed in accordance with NFPA 2001.

- UL listed and FM approved.

- Marine system with USCG and ABS approvals also available.